Online moisture measurement in iron ore

- 4 minutes read - 665 wordsMoisture measurement in iron ore is a long standing issue as iron ore miners aim to suppress dust, keep material below the TML and customers don’t want to pay for water.

Pilbara Iron Ore is predominantly a mixture of the following minerals:

| Mineral | Composition | H2O |

|---|---|---|

| Hematite | Fe2O3 | 0 |

| Goethite | FeOOH | 0.1013 |

| Kaolinite | Al2Si2O5(OH)4 | 0.1395 |

| Quartz | SiO2 | 0 |

| Limonite | FeO(OH)·nH2O | 10+ |

most of them contain water (or OH bonds) in their structure and natural minerals will vary much more than their ideal composition.

Regarding measurement techniques there are multiple providers of equipment using the following methods:

- NIR

- Microwave

- Neutrons

It’s important to note all of the above methods measure total water (free, bound, mineralogical) interference from hydrated minerals should be expected.

This variability in mineralogical water content limits the performance of any instrument measuring water content of a mass of material travelling on a conveyor belt.

Unless you know the current composition of the material travelling through the sensor you cannot isolate the effect of changing the water content vs a change in the mineralogical composition.

To demonstrate the problem we will use open file data from both DMIRS and the NVCL, unfortunately I coundn’t find any hylogger scanned drillholes in either brockman or marra mamba so I’ll be using data from the boolgeeda iron formation; specifically ATLAS iron’s Jimblebar project.

As there are no assays for the diamond hole we are going to have to use the assay results from the RC twin that is approximately 10m away.

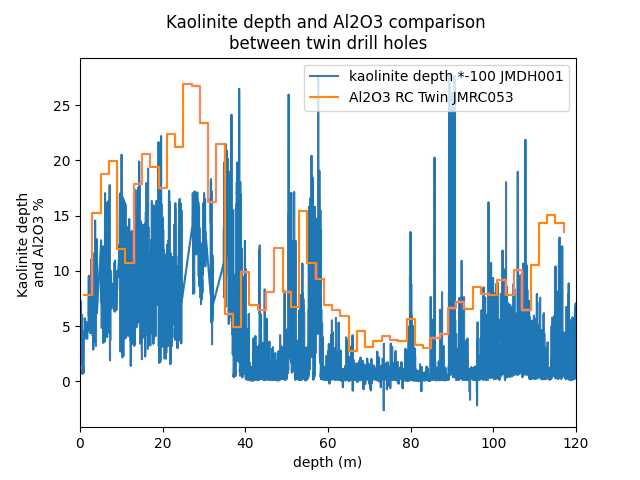

Let’s first plot Al2O3 from the RC twin and the depth of the 2200nm feature to demonstrate that the diamond hole and it’s twin are sufficiently correlated.

There is an approximately 1-2m offset that changes across the hole pairs, we accept this as sufficient for this analysis.3

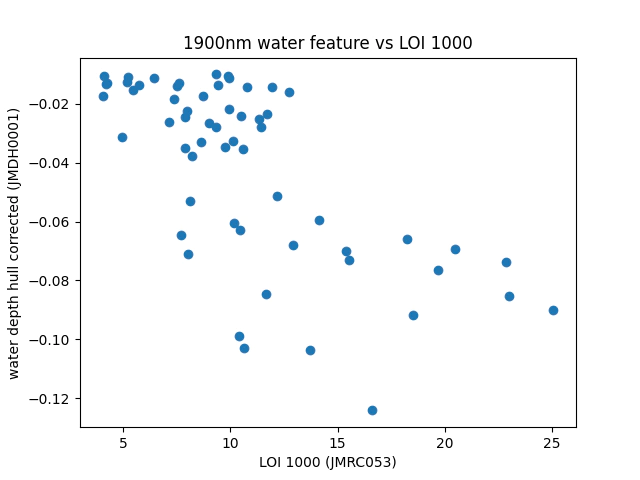

Next we composite the drill core spectra to the same intervals as the RC twin, we then extract the 1900nm water feature depth as outlined in Rodger et al and plot that feature against the LOI from the twin hole.1,2

This dataset only contains analysis for LOI1000 which includes carbonate and pyrite decomposition and limits the correlation between the water depth and LOI.

Even with these caveats it can be seen that there is a strong relationship between the depth of the 1900nm water feature and the LOI.

It is also important to note these measurements are taken on air dried core in a lab setting so the vast majority of variation of the 1900nm water feature is due to the slight changes in composition of the material, not changes in the amount of water on the core.

The practical implications of this for an on conveyor moisture measurement system are that you can expect that your NIR, Microwave or Neutron instrument will suffer drift due to the material composition changing.

The solution is thus to have an instrument that quantifies the mineral compositions as well as the amount of water on the belt.

Footnote:

The twin is approximately 10m away, I do understand that you shouldn’t do this but we make do with what we have. Ideally we would simply use the assays from the Met samples that this hole has taken. Unfortunately the met sampling is made of composites between holes (JMDH001, JMDH002) and the second hole is not scanned with hylogger.

Another fun fact is that the twin data is not in the DMIRS database, but is reported in the correct format in geodocs which makes me wonder how much reported data is not in the database.

I know DTW exists and that it would be excellent in this use case but I don’t want to fiddle around with it.

References:

Michael C. Munro and Abbas Mohajerani Moisture content limits of Iron Ore Fines to prevent liquefaction during transport: Review and experimental study https://www.sciencedirect.com/science/article/abs/pii/S0301751616300175

Rodger, A.; Ramanaidou, E.; Laukamp, C.; Lau, I. A Qualitative Examination of the Iron Boomerang and Trends in Spectral Metrics across Iron Ore Deposits in Western Australia. Appl. Sci. 2022, 12, 1547. https://doi.org/10.3390/app12031547