MWD cavity detection and background rates Part 4

- 3 minutes read - 502 wordsHi All,

Let’s talk about improving these estimates or how to do a site specific adjustment.

Revisiting the literature I found this paper Álvaro Corral, Álvaro González (2019). Power Law Size Distributions in Geoscience Revisited one could argue (but you won’t argue) that I should use a power law distribution for the cavities instead of an exponential, but that would require two parameters instead of one and it is easier to reason with less parameters at least initially.

One of relevant referenced items was this Taylor, R. L., Florea, L., Caudill, M., & Currens, J. C. (2003). A GIS sinkhole coverage for the karst areas of Kentucky (Tech. Rep.): Kentucky Geological Survey. There are two very interesting points that can be taken from this dataset:

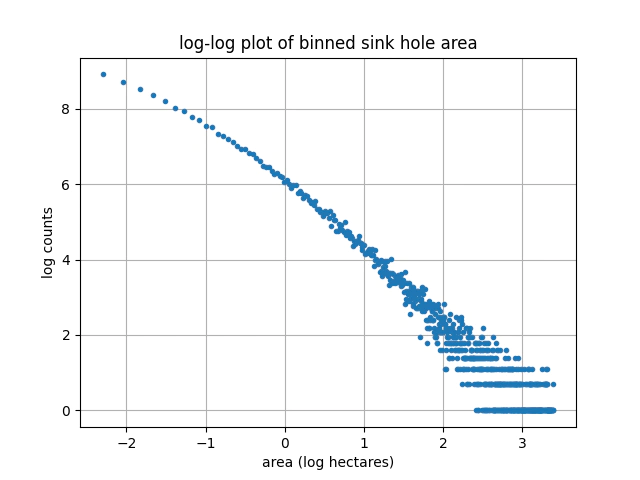

- The distribution of sinkholes areas follows a power law distribution

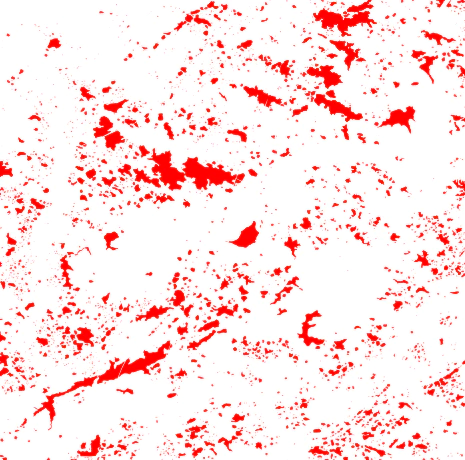

- The shape of the sinkhole areas are not at all circular. We could use these shapes to validate how much difference there is in detectability between assumed circular cavities and the actual shapes we see in nature the example below is from sinkhole data.

To improve your estimate of the background risk you need to have a site specific dataset of cavity sizes and shapes. Unfortunately standard single or triple arm calipers are limited in their maximum diameter and generally speaking don’t have multiple independent arms to at least measure the eccentricity of the hole, multifinger tools are available but of course come at increased price.

Other downhole tools such as acoustic televiewers have high resolution but hole conditions can reduce the quality of the returned signal and a deal breaker for much of iron ore is that they must be run below the water table.

Going the non-downhole tool route to estimate the liklihood of cavities you could consider both seismic and ground penetrating radar (GPR) for smaller cavities you are still going to have detection issues.

The biggest gain here is that you may be able to assess both the shape and size of the cavities rather than the assumed circular shapes that we have used previously. Be aware that when using the geophysical methods you need to select ground that you are confident contains cavities and has enough geophysical contrast to work.

A possible option for iron ore is to fly a drone with a side scan lidar around the sides of the hills to find any caves and scan their internal shapes this would have the advantage of putting some constraints on the largest cavity size.

You could integrate this with the caliper and geophysical data to end up with pretty decent constraints on size and distribution.

To conclude there would be a good opportunity for the iron ore industry to band together and share cost and risk reduction information in a collaborative way, perhaps this is a good example of something DMIRS could run as a workshop?

Thanks,

Ben.